Level 1

Section 5.5: Conventional laser machining of materials

Lasers can be divided into gas, solid state and liquid lasers according to the individual Common Industrial Lasers at Level 1 section 2.6.

CO2 laser machining of materials

Molecular Gas Lasers lasers exploit transitions between the energy levels of a molecule. Depending on the type of transition involved, molecular gas lasers belong to one of the following categories:

CO2 Laser

As the active medium, these lasers use a suitable mixture Of CO2, N2, and He. Oscillation takes place between two vibrational levels of the CO2 molecule, while N2 and He greatly improve the efficiency of laser action. The CO2 laser is actually one of the most powerful lasers (output powers of more than 100 kW have been demonstrated from a CO2 gas-dynamic laser) and one of the most efficient (15-20% slope efficiency). Nitrogen helps producing a large population in the upper laser level while helium helps removing population from the lower laser level.

Fig. 1 Carbon Dioxide Energe Levels

Figure (1) shows the relevant vibrational energy levels for the electronic ground states of the CO2 and N2 molecules. The N2 molecule, being diatomic, has only one vibrational mode; its lowest two energy levels (v= 0, v = 1) are indicated in the figure. Energy levels for CO2 are more complicated, since CO2 is a linear triatomic molecule. In this case, there are three nondegenerate modes of vibration: Symmetric stretching, bending, and asymmetric stretching.

The remaining energy between the intermediate states and the ground state is lost through kinetic energy transfer, which generates heat instead of light. For CO2 molecules, the rate of energy release through heat is much lower than energy release through light, so the energy efficiency for producing a laser beam is high compared with other lasing materials. In comparison, helium has a very high thermal diffusivity; therefore, with its addition to the lasing gas mixture, the rate of energy release through heating is extremely high. This combination of lasing interactions makes the carbon dioxide laser suitable for industrial applications in terms of both the energy efficiency (up to 10%) and the high output beam powers achievable.

The three main types of gas flow are sealed discharge tube, axialflow, and traverse or crossflow. The flow method determines how fast the post-stimulation carbon dioxide gas can be removed from the optical cavity so that new ground state carbon dioxide gas can be introduced for excitation and stimulation.

1. The sealed discharge laser contains a fixed lasing gas mixture sealed in the laser cavity; therefore, it does not require a gas supply or gas handling system. However, because there is no gas flow, output powers are limited to about 50 W (since used CO2 cannot be discharged and replenished with new CO2), and the lifetime of the laser is limited by the disassociation of the carbon dioxide into oxygen and carbon monoxide.

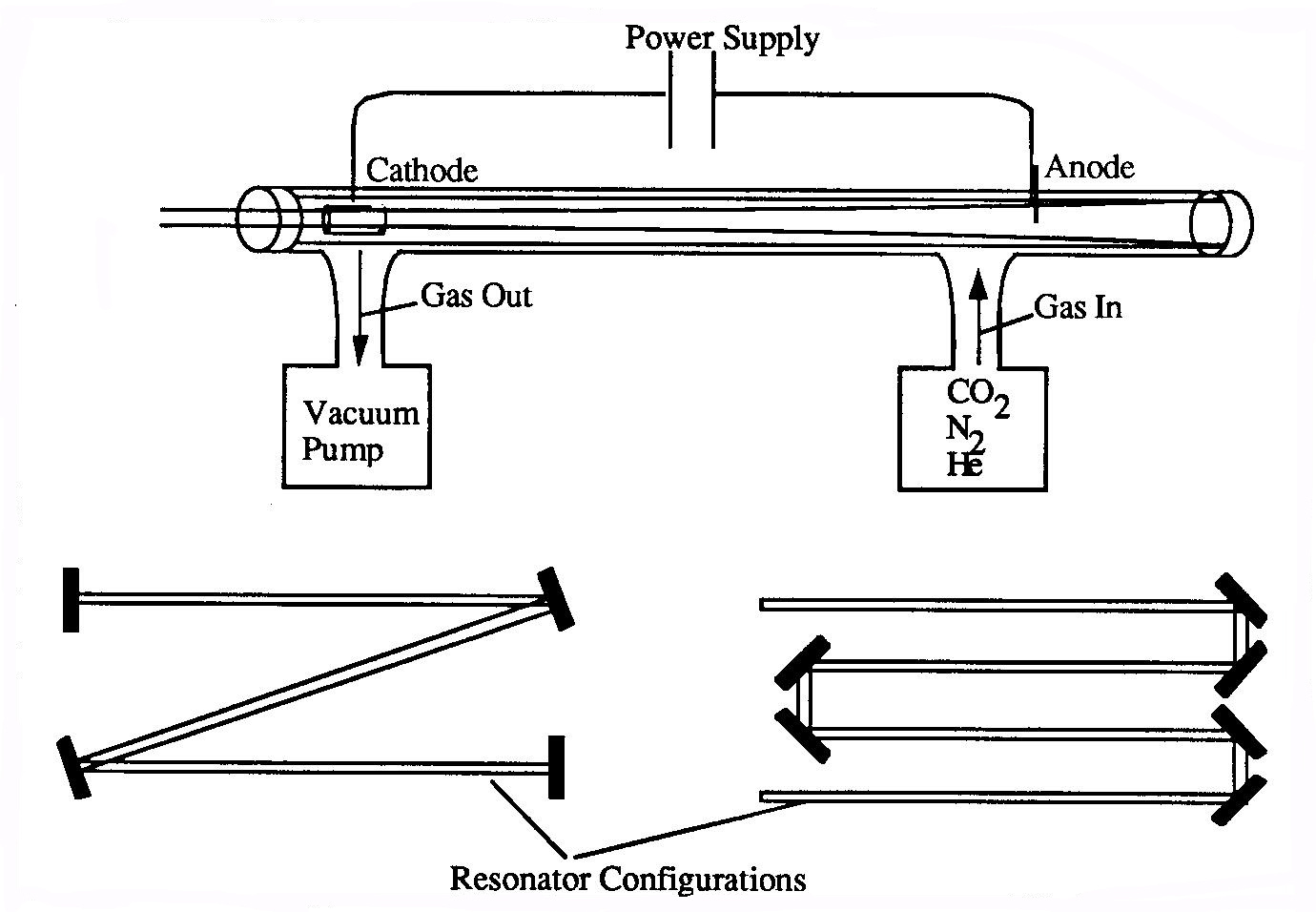

2. The second type Of CO2 laser is the axialflow laser. This is the most widely used type of CO2 laser, in which the gas flows along the axis of the optical cavity (Fig.2) Axial flow allows the depleted gas to be replaced by new gas. Laser beam powers of up to 4 kW of continuous wave output can be achieved. Laser beams with pure Gaussian intensity profiles can be generated for power levels up to about one kW, while beams with power above one kW generally have a mixed mode output containing two or mom different intensity profiles. Since the used gas is either exhausted immediately or is reused after removing any contaminants, this system requires a constant supply of gas and a gas handling system. Axial flow lasers can be further classified by the speed of gas flow, namely low-speed flow and high-speed flow lasers. Low-speed flow lasers attain power outputs of about 50 W to 70 W for each meter of cavity length. To produce a compact package, the optical cavity is folded so that longer discharge lengths can be obtained in a smaller assembly. The low flow speed causes the laser to heat up considerably, and the relatively low conductivity of the gas mixture limits the bore size of the lasing tube. Heating of the resonator cavity causes distortions in the resonator optics due to thermal expansion; these distortions affect the beam intensity profile and beam stability. However, with external cooling for the resonator and optics, beam outputs with good adjustability and stability can be generated. Mgh-speed flow models typically have a gas velocity of 60 nVs. Thus, the carbon dioxide molecule only has time for one excitation/stimulation cycle before exiting the optical cavity. Typical outputs are 600 W per meter of cavity length, with total laser beam outputs available up to 6 kW. Due to the convective cooling of the high-speed flow, the thermal distortions in the resonator optics are minimized and larger bore diameters can be used to produce intensity profiles which are nearly Gaussian in shape.

Fig. 2 Axial Flow CO2 laser (After Chryssolouris, 1991)

Excimer laser machining of materials:3.The third type Of CO2 laser is the transverse flow laser (Figure 3), in which the gas mixture of He, N2 and CO2 flows perpendicular to the optical cavity axis. The gas flow is maintained by a blower and is cooled by a heat exchanger. The electrodes are arranged on either side of the cavity, and relatively small voltages are required in order to maintain high current discharge due to the small separation distances. The beam is usually reflected or folded several times within the cavity, creating a compact design which can achieve outputs of one to 10 kW per meter of cavity length and total outputs greater than 15 kW. However, beam quality deteriorates at higher power levels and beam output can shift between several possible beam intensity profiles.

Fig. 3 Transverse flow CO2 laser (After Chryssolouris, 1991)

Sealed-off TEA CO2 laser: A transversely excited atmospheric (TEA) CO2 laser with gas internal coaxial circulation scheme attract more interest nowadyas becuase of its convinience, low cost, and flexibility. The CO2-N2-He gas is circulated internally so that the system is compact and easy to maitain. Up to 500W Sealed-off TEA CO2 laser is availible now. Guo, Zhen, et. al., (1994) employed the free potential plate UV corona preionization technique to ensure stable discharge. Gorkin, S.B et. al.(1994) investigate the influence of plasma-chemical reactions products, heat processes on the electrode surface, and the degree of coordination of pump pulse generator on the forming conditions of volume discharge in the working mixtures of sealed-off TEA CO2 laser. Jiang, Dong, et. al.,(1996) gives some results and curves from digital calculating about equations of TEA CO2 laser. 3D Chang's electrode was precisely calculated and manufactured to gain well-distributed electric field in discharge space, which is necessary for TEA CO2 laser. A pre-ionization technique used in this laser was described. A gas circulating system was designed to let the laser operate at high repetition frequency (HRF). It is a key technique to extend the operating life of mini high repetition frequency sealed-off TEA CO2 laser. So, an efficient low temperature catalyst is used in this laser. Mini HRF sealed-off TEA CO2 laser can be applied for the military such as rangefinder, tracing, designating, etc.

The wide range of laser beam power levels is contributed to the several geometry of electronical discharge and gas flow, from several Watts to 15kW. High power carbone dioxide lasers typically operate with mixed energy intensity distributions; the beam profile may vary with time between several possible configurations. Medium and low powered CO2 lasers are more stable and maitain a Gaussian intensity distribution. CO2 lasers are widely used in industry for applications in laser machining, welding and heat treating. CO2 laser machinging of metals ,polymers, composite, semiconductor was introduced in level1, section 5.1, 5.2, 5.3, 5.4.

Fundamentals of excimer laser:

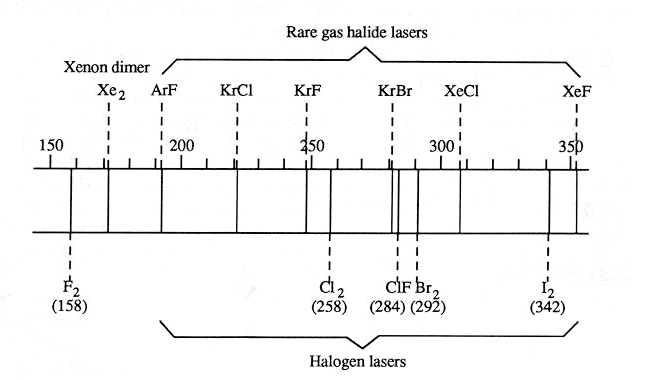

Excimer Lasers represent an interesting and important class of molecular laser involving transitions between different electronic states of special molecules referred to as excimers. Excimer laser is an increasingly popular type of gaseous laser. The term "excimer" originates from "excited dimer," a compound of two identical species which exists only in an excited state. Some excimer lasers use xenon (Xe2) and fluorine (F2) as the lasing material, but the majority of excimer lasers use an excited complex (exciplex) of a noble gas and halogen atom as the actual lasant. Typical excimer complexes include argon fluoride (ArF), krypton fluoride (KrF), xenon fluoride (XeF), and xenon chloride (XeCl). These compounds only exist temporarily when the noble gas is in an excited electronic state. The bond is very strong but lasts only a few nanoseconds. When the noble gas atom is no longer excited, each compound molecule dissociates into its elemental components; this dissociation is accompanied by a release of the binding energy in the form of a photon. The output wavelengths of the excimer lasers vary from 0.193 to 0.351 microns in the ultraviolet to near-ultraviolet spectra (Figure 4)

Fig. 4 Spectra for different types of excimer lasers

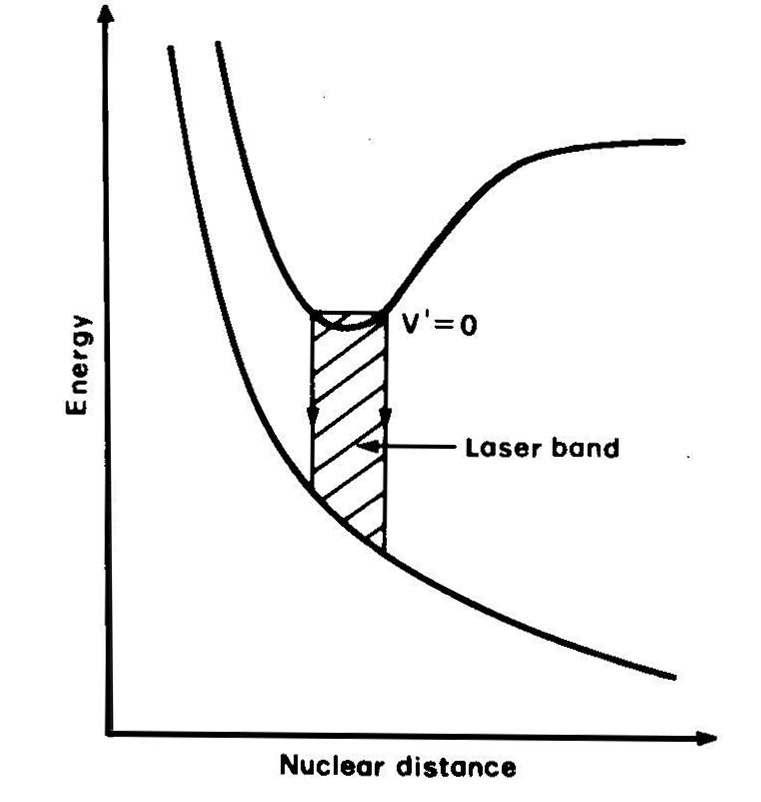

Consider a diatomic molecule A2 with potential energy curves as in Figure (5) for ground and excited states, respectively. Since the ground state is repulsive, the molecule cannot exist in this state; i.e., the species exists only in the monomer form A in the ground state. However, since the potential energy curve shows a minimum for the excited state, the species is bound in this state; i.e., it exists in dimer form. Such a molecule A2* is called an excimer, a contraction of the words excited dimer. Suppose that a large fraction of excimers are somehow produced in the given volume of the medium. Under appropriate conditions, laser action can then occur on the transition between the upper (bound) state and the lower (free) state (bound-free transition). This is referred to as an excimer laser; a classical example is the Ne* laser, the first excimer laser to be operated (A = 170nm).

Fig. 5 Energe state of excimer lasers

Excimer lasers

have three notable and important properties: (1) Since the transition occurs

between different electronic states of a molecule, the corresponding transition

wavelength generally falls in the UV spectral region. (2) Once the molecule

reaches the ground state, having undergone stimulated emission, it rapidly dissociates

due to the repulsive potential of this state. This means that the lower laser

level can be considered empty, so the laser operates according to the four-level

laser scheme. (3) Due to the lack of energy levels in the ground state, no rotational-vibrational

transitions there exist and the transition is observed to be featureless and

relatively broad (![]() ). Note, however,

that, in some excimer lasers, the energy curve of the ground state does not

correspond to a pure repulsive state, but it features a (shallow) minimum. In

this case the transition occurs between an upper bound state and a lower (weakly)

bound state (bound- bound transition). However, since the ground state is only

weakly bound, a molecule in this state undergoes rapid dissociation either by

itself (a process referred to as predissociation) or as a result of the

first collision with another species of the gas mixture. Thus, in this case

also, light emission produces a continuous spectrum.

). Note, however,

that, in some excimer lasers, the energy curve of the ground state does not

correspond to a pure repulsive state, but it features a (shallow) minimum. In

this case the transition occurs between an upper bound state and a lower (weakly)

bound state (bound- bound transition). However, since the ground state is only

weakly bound, a molecule in this state undergoes rapid dissociation either by

itself (a process referred to as predissociation) or as a result of the

first collision with another species of the gas mixture. Thus, in this case

also, light emission produces a continuous spectrum.

The excimer is usually formed in a rectangular resonator cavity. The output beam originates from the resonator and the discharge is transverse. The emission spectrum of photons is a wide (100-200A) continuous band. This width causes the stimulated cross section to be small, so that high excimer concentrations are required for amplification. Often, all the gases may be used with a single excimer laser, however, the laser must be conditioned between each gas. The halogens react with the materials of the laser, so an inert gas such as He or Ar needs to be flushed through to break up the compounds.

Excimer lasers produce high-powered, pulsed beams, with average power over 100W and average pulse repetition rate of 1000 pulses per second. The problem with a high average power is that the lasing medium and the resonator cavity are both heated during the lasing process. At the same time, high power levels must be reached in order to achieve reliable periodic switching [9]. In the excimer compound, both intermediate products (F-, Ar2+, etc.) and active states of the molecule (KrF*, XeF*, etc.) absorb the laser radiation with an absorption coefficient between 1x 10-3 cm-1 and 5 x 10-3 cm-1. This fact limits the length (L) of the laser to 2-3 m because the coefficient x L must be less than or equal to one; otherwise, all of the beam energy will be absorbed by the excimer and no laser beam can be produced. This shorter length limits the maximum output energy of the excimer laser, which makes the range of materials it can process much narrower than that for the CO2 laser. The instability of the discharge, the inhomogeneity of the excimer, and the chemical and thermal effects on the medium limit the average power of an excimer laser pumped by an electrical discharge. In KrF, XeF, and XeCl lasers, this problem is addressed by driving the gas mixture rapidly and perpendicularly to the discharge zone.

Since the pressure of the gas mixture is above atmospheric pressure, Excimer lasers can be operated only in a pulsed regime. Furthermore, due to the shorter lifetime of the upper state and to avoid the onset of arc formation, faster pumping is usually provided for excimer lasers compared to TEA CO2 lasers. (Pump duration of 10-20 ns is typical.) For standard systems, preionization is achieved by a row of sparks. For the largest systems, more complex preionization arrangements are adopted, which use either an auxiliary electron beam or a x-ray source.

Excimer lasers with high repetition rates (up to -500 Hz) and high average power (up to 100w) are commercially available, while larger laboratory systems exist with a higher average power (in excess of a few kilowatts). The efficiency of these lasers is relatively quite high (2-4%) as a result of the high quantum efficiency and the high efficiency of the pumping processes.

Application:

Excimer lasers are used to ablate plastics as well biological materials with great precision, since these materials exhibit strong absorption at UV wavelengths. In fact, in some of these materials, the penetration depth for each laser pulse may be only a few micrometers. Due to the strong absorption and short pulse duration, a violent ablation process is produced, wherein the material is directly transformed into volatile components. Applications include drilling very precise holes in thin plastic films (as used, e.g., in the ink jet printer head) and corneal sculpting, to change the refractive power of the eye and hence correct myopia. In the field of lithography, the 248-nm UV light provides a good illumination source for achieving submicron-size features in semiconductor microchips. Excimer lasers can also be used as dye laser pumps, since most dyes absorb strongly in the UV.

Excimer lasers are also used to machine solid polymer workpiece, remove polymer films from metal substrates, remove metal films from polymer substrates, micromachine ceramics and semiconductors, and mark thermally sensitive materials, among other things. The characteristics of the excimer laser beam make it ideal for some material removal applications. The high energy of each photon from an excimer laser reduces the interaction time between the irradiated and bulk material of the workpiece; therefore, the heat-affected zone is minimized. This is extremely desirable for surgical and polymer processing applications and can be applied to other materials such as ceramics as soon as higher average power models are developed. The use of excimer lasers for cutting, drilling and marking has increased since their development in the 1970s. Processing with excimer lasers results in higher precision and reduced heat damage zones compared with CO2 and ND:YAG lasers. The increased demand for excimer lasers in recent years has resulted in the development of more reliable lasers by manufacturers. The fact that industry has become more aware of the applications of excimer lasers has caused their use in materials processing to become more acceptable.

The physics of the material removal process for excimer lasers is different than that for CO2 or ND:YAG lasers. Instead of removing material through melting or vaporization, where the material is heated from solid to liquid and/or gaseous states, the excimer laser removes material through ablation, breaking the chemical bonds of the material until it dissociates into its chemical components. In ablation, no liquid or gaseous phases of the material are present. The ablation process occurs as the UV pulses of radiation from the excimer laser make contact with the workpiece surface. Organic materials absorb photons in a thin layer near the surface, which break the bonds in the organic compounds. When the rate of bond breaking exceeds a critical value, the material decomposes. In this manner, the pulse of the excimer beam removes a fraction of a micrometer-thick piece of material layer by layer.

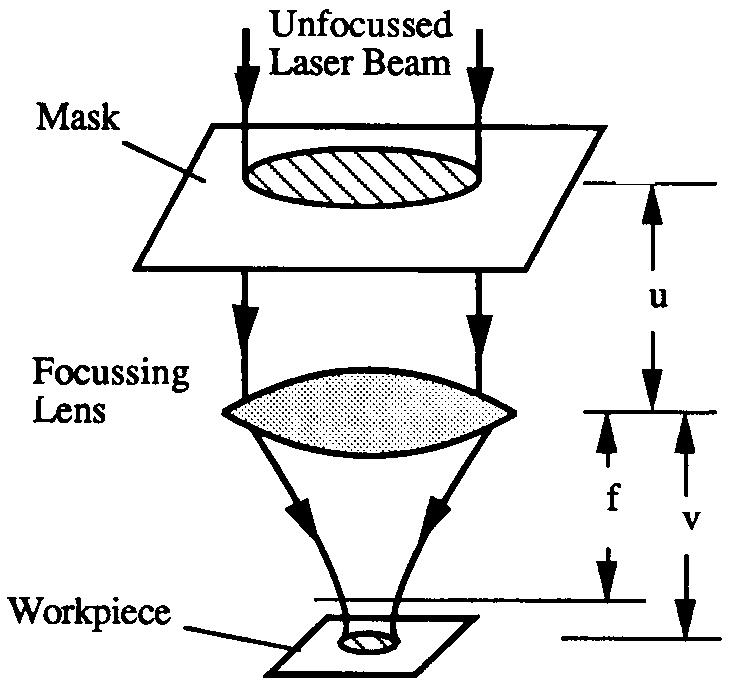

Another difference between excimer and CO2 or YAG lasers is that the latter focus the beam to a small area and traverse the workpiece. Excimer lasers produce large area beams that are masked through a template to achieve the desired cutting area (Figure 6). After being passed through a mask, the beam is focused onto the workpiece through a lens.

Fig. 6 Configuration for laser machining with an Excimer Lasers (After Chryssolouris, 1991)

The energy density at the workpiece can be changed by adjusting the degree of demagnification. Since unfocussed excimer laser beams usually have energy densities from 100 to 200 mJ/cm2, processing of polymers, for example, requires a demagnification factor of two to three. An added advantage is that the dimensional accuracy of the shape machined in the workpiece is high compared with the template shape, since there is no relative motion between the beam and the workpiece.

The mask is made of a metal that reflects most of the incident laser irradiation, so the material underneath the mask is not removed in the cutting process. Excimer lasers are excellent for machining repetitive patterns because the use of the mask allows for a series of holes or slits to be processed at the same time. This method is much more efficient than the use of a CO2 or ND:YAG laser, whose use requires that each hole or slit be cut individually. For example, an excimer laser can drill 5000 holes in a polyirnide sheet in approximately 3 seconds, while the same process would require about 50 seconds with a CO2 or Nd:YAG laser . Excimer laser machinging of metals ,polymers, composite, semiconductor was introduced in level1, section 5.1, 5.2, 5.3, 5.4.

YAG laser machining of materials

Fundamentals:

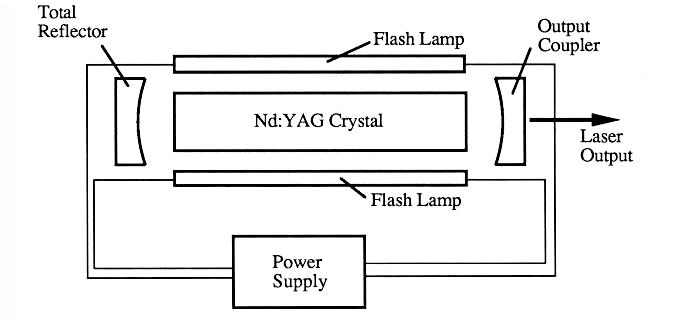

ND:YAG laser is one of Solid State Lasers. Solid lasers use ions suspended in a crystalline matrix to produce laser light. The ions or dopants provide the electrons for excitation, while the crystalline matrix propagates the energy between ions. The two main classes of dopants in the laser medium are Chromium (Cr3+) for ruby lasers and Neodinium (Nd3+) for ND:YAG and ND:glass lasers. The ND:YAG and Nd:glass lasers are in general very similar to each other in structure and lasing action. Excitation is achieved by krypton or xenon flash lamps, and an output wavelength of 1.06gm in the near infrared region of the spectrum is obtained. The Nd:glass laser uses a glass host material for the neodymium ions. The glass rods have the advantage that they can be grown to larger sizes more economically than the YAG crystals, but glass has a lower thermal conductivity which limits the pulsed operation of the Nd:glass laser. Therefore, Nd:glass lasers are used in applications which require low pulse repetition rates and high pulse energies (up to 100 Joules per pulse). In general, the pulse operation of the neodymium lasers make them desirable for hole piercing and deep keyhole welding applications.

The host material in ND:YAG lasers is a complex crystal of Yttriurn-Aluminum-Garnet (YAG) with the chemical composition Y3AI5O12. Figure (7) shows the schematic of a Nd:YAG Laser. The YAG crystal has a relatively high thermal conductivity, which improves thermal dissipation in the laser cavity, so continuous wave operation up to a few hundred Watts is possible. When operated in a pulsed mode, high pulsing rates can be achieved, and average powers of up to 1 kW are available. The actual lasant is the Nd+3 ions which have been doped into a YAG crystal. The YAG crystal is transparent and colorless. When doped with approximately 1% Nd, the crystal takes on a light blue color.

Fig. 7 Schematic of Nd:YAG Laser (After Chryssolouris, 1991)

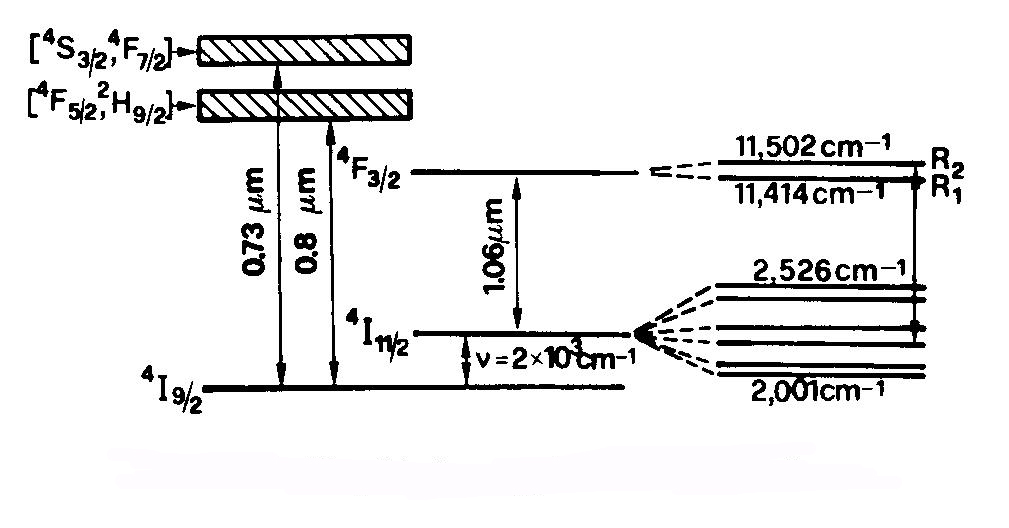

Figure 8 shows a simplified energy level scheme for ND:YAG. These levels arise from the three inner-shell 4f electrons of the Nd3+ ion, which are effectively screened by eight outer electrons (5S2 and 5 P6). The crystal field of YAG only weakly influences energy levels, so the Russell-Saunders coupling scheme of atomic physics can be used. Level notation is accordingly based on this scheme, and the symbol characterizing each level has the form 2S+1LJ where S is the total spin quantum number, J is the total angular momentum quantum number, and L is the orbital quantum number. The 4I9/2 ground level correspond to a state in which 2S+1= 4 (i.e., S = 3/2), L = 6, and J = L-S = 9/2. Each level is (2J + 1)-fold degenerate corresponding to the quantum number mj running from -J to + J in unit steps. Note that, since the degeneracy of all sublevels is always the same (i.e., g = 2), we can disregard this degeneracy and consider each sublevel in Figure (8) as if it were a single nondegenerate level.

Fig. 8 Simplified energy levels of Nd:YAG

Generally, a cooling system is required for operation of ND:YAG lasers. With an efficiency of about 3%, a typical ND:YAG produces thirty times as much waste heat as laser output; this heat must be removed in order to ensure proper laser operation. Flooding the optical compartment with water can remove waste heat; however, the water absorbs a significant amount of the flashlamp energy, and the turbulence of the water can produce optical distortion and imaging problems. These problems can be overcome by flowing water over the outside of the optical cavity and by encasing the lasing rod and flashlamp with transparent cooling jackets. Furthermore, the flashlamp electrode assemblies should be cooled to prevent thermal loading, and deionized water should be used to prevent any electrical conduction through the water.

The, output characteristics of a ND:YAG laser can be altered by varying the pumping discharge waveform. For high pulse energy in a pulse time of one millisecond, a long lamp pulse is used to obtain a six to seven Joule pulse composed of many spiked oscillations within the pulse. Such a laser can operate at several hundred cycles per second and is useful in laser cuttings. Laser beam pulse frequency and shape can be tailored by using Q switching, where a shutter moves rapidly in and out of the path of the beam. In this manner, beam output is interrupted until a high level of population inversion and energy storage is achieved in the resonator. If the optical cavity is switched from no reflections (low Q) to near total reflection (high Q), the cycle can be optimized to build up the maximum population inversion before the pulse is generated (switched from low to high Q). This results in a beam pulse with a high energy (up to one joule) and a short pulse period (down to 10 ns), which is especially useful for deep hole drilling applications.

Applications:

ND:YAG lasers are widely used in a variety of applications, including:

Nd:YAG laser machinging of metals ,polymers, composite, semiconductor was introduced in level1, section 5.1, 5.2, 5.3, 5.4.