Level 1

Section 5.6: CO2 laser machining of materials

Molecular Gas Lasers lasers exploit transitions between the energy levels of a molecule. Depending on the type of transition involved, molecular gas lasers belong to one of the following categories:

CO2 Laser

As the active medium, these lasers use a suitable mixture Of CO2, N2, and He. Oscillation takes place between two vibrational levels of the CO2 molecule, while N2 and He greatly improve the efficiency of laser action. The CO2 laser is actually one of the most powerful lasers (output powers of more than 100 kW have been demonstrated from a CO2 gas-dynamic laser) and one of the most efficient (15-20% slope efficiency). Nitrogen helps producing a large population in the upper laser level while helium helps removing population from the lower laser level.

Fig --. Carbon Dioxide Energe Levels

Figure (---) shows the relevant vibrational energy levels for the electronic ground states of the CO2 and N2 molecules. The N2 molecule, being diatomic, has only one vibrational mode; its lowest two energy levels (v= 0, v = 1) are indicated in the figure. Energy levels for CO2 are more complicated, since CO2 is a linear triatomic molecule. In this case, there are three nondegenerate modes of vibration: Symmetric stretching, bending, and asymmetric stretching.

The remaining energy between the intermediate states and the ground state is lost through kinetic energy transfer, which generates heat instead of light. For CO2 molecules, the rate of energy release through heat is much lower than energy release through light, so the energy efficiency for producing a laser beam is high compared with other lasing materials. In comparison, helium has a very high thermal diffusivity; therefore, with its addition to the lasing gas mixture, the rate of energy release through heating is extremely high. This combination of lasing interactions makes the carbon dioxide laser suitable for industrial applications in terms of both the energy efficiency (up to 10%) and the high output beam powers achievable.

The three main types of gas flow are sealed discharge tube, axialflow, and traverse or crossflow. The flow method determines how fast the post-stimulation carbon dioxide gas can be removed from the optical cavity so that new ground state carbon dioxide gas can be introduced for excitation and stimulation.

1. The sealed discharge laser contains a fixed lasing gas mixture sealed in the laser cavity; therefore, it does not require a gas supply or gas handling system. However, because there is no gas flow, output powers are limited to about 50 W (since used CO2 cannot be discharged and replenished with new C02), and the lifetime of the laser is limited by the disassociation of the carbon dioxide into oxygen and carbon monoxide.

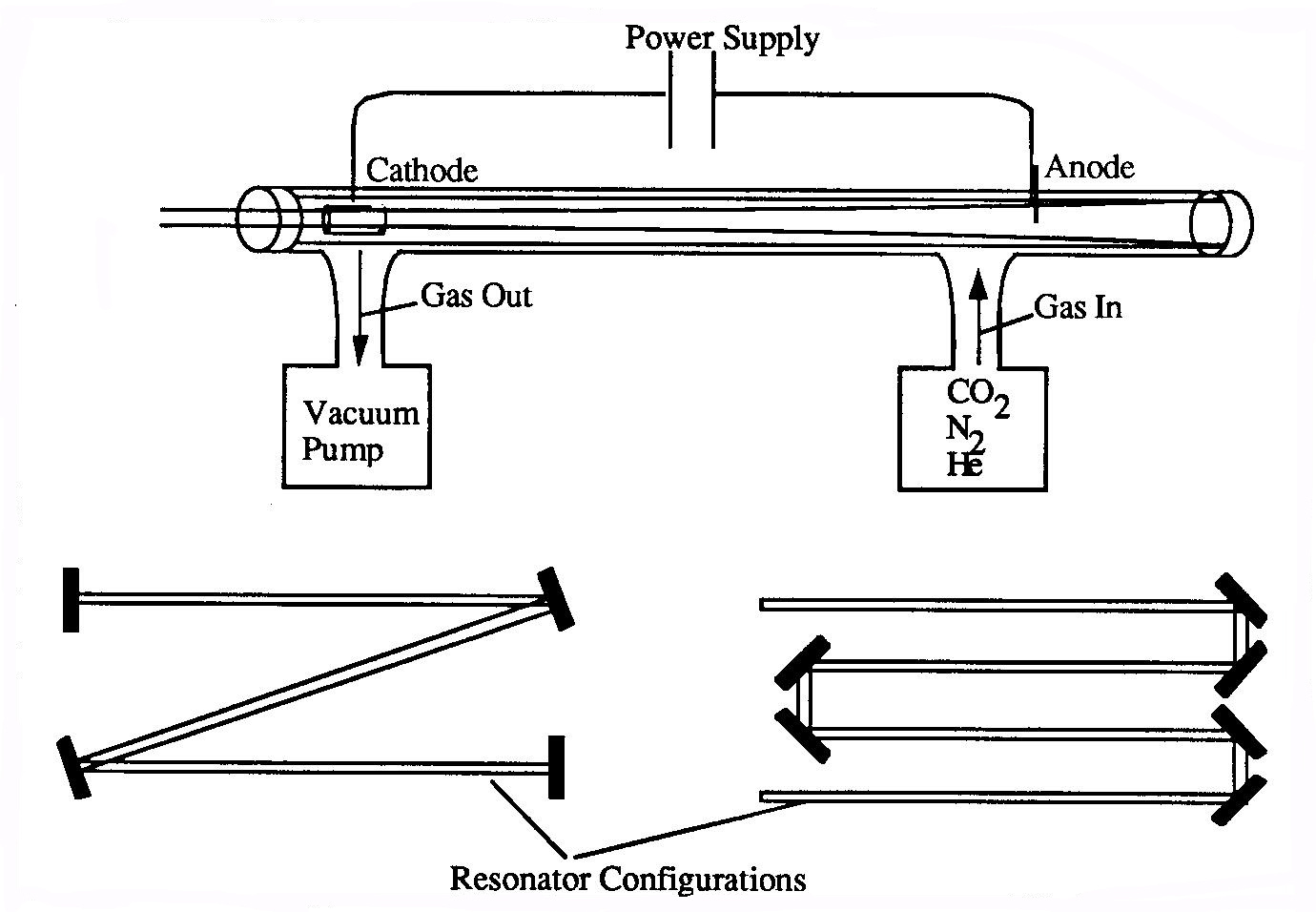

2. The second type Of CO2 laser is the axialflow laser. This is the most widely used type of C02 laser, in which the gas flows along the axis of the optical cavity (Fig---). Axial flow allows the depleted gas to be replaced by new gas. Laser beam powers of up to 4 kW of continuous wave output can be achieved. Laser beams with pure Gaussian intensity profiles can be generated for power levels up to about one kW, while beams with power above one kW generally have a mixed mode output containing two or mom different intensity profiles. Since the used gas is either exhausted immediately or is reused after removing any contaminants, this system requires a constant supply of gas and a gas handling system. Axial flow lasers can be further classified by the speed of gas flow, namely low-speed flow and high-speed flow lasers. Low-speed flow lasers attain power outputs of about 50 W to 70 W for each meter of cavity length. To produce a compact package, the optical cavity is folded so that longer discharge lengths can be obtained in a smaller assembly. The low flow speed causes the laser to heat up considerably, and the relatively low conductivity of the gas mixture limits the bore size of the lasing tube. Heating of the resonator cavity causes distortions in the resonator optics due to thermal expansion; these distortions affect the beam intensity profile and beam stability. However, with external cooling for the resonator and optics, beam outputs with good adjustability and stability can be generated. Mgh-speed flow models typically have a gas velocity of 60 nVs. Thus, the carbon dioxide molecule only has time for one excitation/stimulation cycle before exiting the optical cavity. Typical outputs are 600 W per meter of cavity length, with total laser beam outputs available up to 6 kW. Due to the convective cooling of the high-speed flow, the thermal distortions in the resonator optics are minimized and larger bore diameters can be used to produce intensity profiles which are nearly Gaussian in shape.

Fig --. Axial Flow CO2 laser

3.The third type Of CO2 laser is the transverse flow laser, in which the gas mixture of He, N2 and CO2 flows perpendicular to the optical cavity axis. The gas flow is maintained by a blower and is cooled by a heat exchanger. The electrodes are arranged on either side of the cavity, and relatively small voltages are required in order to maintain high current discharge due to the small separation distances. The beam is usually reflected or folded several times within the cavity, creating a compact design which can achieve outputs of one to 10 kW per meter of cavity length and total outputs greater than 15 kW. However, beam quality deteriorates at higher power levels and beam output can shift between several possible beam intensity profiles.

Fig--. Transverse flow CO2 laser