Section 2.1: Diode Pumped Lasers Overview

The process by which atoms are raised from lower level to upper level is called pumping. Diode pumped lasers are becoming more and more important in laser machining. Before we describe diode pumped lasers in detail, letís first review the common pumping methods, so that we can appreciate the advantages of diode laser pumping.

Pumping is usually performed in the following forms:

First, Optical Pumping. Optical pumping uses either cw or pulsed light emitted by a powerful lamp or a laser beam. Optical pumping can be realized by light from powerful incoherent sources. The incoherent light is absorbed by the active medium so that the atoms are pumped to the upper laser level. This method is especially suited for solid state or liquid lasers whose absorption bands are wide enough to absorb sufficient energy from the wide band incident incoherent light sources.

Optical pumping is a resonant process, the incident photon energy hn must be equal to the energy differences between the excited states and normal states. We can express optical pumping as hn + A à A*, where A is the atom at normal state, A* is the corresponding atom at excited state. So if there are lasers whose light wavelengths are within the absorption bands of the active medium, we can use these laser lights for pumping. Since the bandwidth of laser light is very narrow, the pumping efficiency can be very high. Laser pumping is not limited to solid state lasers, it can also be used for liquid and gas lasers. In fact diode laser pumping will become the dominant means of optical pumping for reasons we talk about later.

Second, Electrical Pumping. Electrical pumping is used for gas and semiconductor lasers. It is realized by allowing a current (continuous dc current, radio frequency rf current or pulsed current) to flow through a conductive medium, such as an ionized gas or semiconductor. Electrical pumping is usually performed by means of sufficiently intense electrical discharge. Gas lasers commonly use electrical pumping or laser pumping, because their absorption bands are narrower than solid and liquid lasers, wide band lamp light is not efficient enough, much of the lamp energy is dissipated as heat. Electrical pumping is non-resonant pumping by electron impact excitation. We can express it as A + e à A* + e-, where A is the atom at normal state, A* is the atom at excited state, e is the incident electron, e- is the electron after energy exchange with the active medium. Electrical pumping is efficient for gases and semiconductors, whose absorption bandwidth is wide enough. Although some optical pumping methods for semiconductor medium have been developed, electrical pumping for semiconductor lasers proved to be more convenient.

The third is Chemical Pumping. For chemical pumping, the population inversion is produced directly by exothermic chemical reaction. Chemical pumping usually applies to materials in gas phase, and generally requires highly reactive and often explosive gas mixtures. The exothermic reaction usually generates large amount of energy, if quite a fraction of this available energy is transferred into laser energy, high power and high energy pulses for lasers can be realized. Chemical lasers have produced maybe the largest cw laser power, 2.2 MW by the MIRACL (Mid-Infrared Advanced Chemical Laser) laser. Such lasers are used as directed energy weapons.

There are other pumping processes such as gas dynamic pumping, etc. We refer the reader to books of lasers on the details of pumping processes. Now letís study more about diode laser pumping.

Laser pumping has been used since the early days of the development of lasers. Laser pumping has become a very important pumping technique since efficient and high-power diode lasers have been developed and widely available in many wavelengths. When we use diode lasers to pump other solid state lasers, we can produce an all-solid state laser.

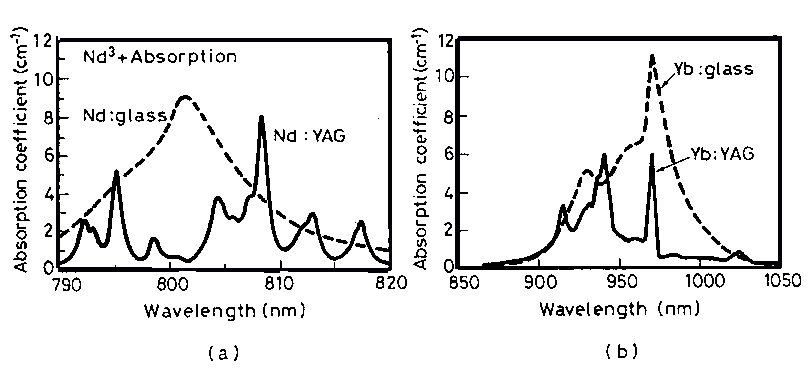

Because optical pumping is a resonant process, the wavelengths of the pumping diode lasers must be within the absorption bandwidth of the active medium to be pumped, the nearer to the absorption peak wavelength the better. The following figure show the absorption spectral of Nd:YAG laser, Nd:glass laser, Yb:YAG laser and Yb:Glass laser. Nd:YAG has a peak absorption value at 810 nm, Nd:glass has a peak value at 802 nm, they can be pumped by GaAs/AlGaAs quantum well (QW) diode lasers at about 800 nm. While for Yb:YAG laser and Yb:glass laser, the best absorption wavelengths are 960 and 980 nm respectively, we can pump them using InGaSa/GaAs strained quantum well (QW) lasers in the 950-980 nm range.

Figure 2.19: Absorption spectral of (a)Nd:YAG/Glass Lasers and (b) Yb:YAG/Glass Lasers

(Orazio Svelto, 1998)

We can divide diode laser pumping into four types according to the degree of integration of the diode lasers: single stripe, diode array, diode bar and diode stack. Normally the pumping power increases with the integration degree.

Common single stripe diode lasers produce powers less than 100mW. With the help of the insulating oxide layer, the diode current is confined to a 3 to 5 m m wide stripe extending over the entire length (100m m) of the diode. The emitted beam is of elliptical shape. In the direction perpendicular to the laser junction the beam diameter is shorter, D%4"H1m m, with a divergence angle of q %4=20° =0.35rad; the beam diameter in the junction plane is longer, D%Q "H3~6m m, with a divergence angle q %Q=5° =0.09rad. Note we have computed the divergence angle using the equation q =2l /p D, since the beam is spatially coherent and diffraction limited. Because of the big difference between the beams in the perpendicular and parallel planes, the beamís major axis direction is rotated 90° after the beam propagates just several micrometers away from the diode exit face, thus transform the beam into circular shape of appropriate size, which is good for pumping.

An array of diode lasers can achieve higher output powers. Suppose the array contains 20 stripes, each 5m m wide, with a separation from centers of about 10m m, the overall dimension of D%Q= 20*10=200m m, D%4 is still 1m m, the divergence angle remains the same because the stripes are not correlated. The output power of diode laser arrays may reach 2W.

To get still higher output powers, the arrays can be serially repeated in a single substrate to form a monolithic bar structure. The output power can be up to 10~20 W. If we make a bar by integrating 20 arrays with centers spaced by 500 m m, each array is 100 m m long and consists of 10 laser stripes, the overall length of the bar is about 1cm.

We can stack the bars into a two dimensional structure, it is reported that 1 cm long bars are stacked to form an emitting area. The average power is about 100W/cm2, peak power 1kW/cm2.

The diode lasers are normally cooled by thermoelectric cooler for low power systems, and by liquid cooling for high powers. Cooling can stabilize the diode laser frequency.

There are basically two types of pump geometry, longitudinal pumping (pump beam enters the laser medium along the resonator axis) and transverse pumping (pump beam incident on the active medium from transverse directions to the resonator axis). For longitudinal pumping, the beam needs to be concentrated to a small and circular spot.

Figure 2.20 : Longitudinal diode laser pumping

Figure 2.21: Transverse diode laser pumping

Next letís estimate the pump efficiency and threshold pump rate, then we will compare diode laser pumping with normal lamp pumping.