Introduction of Laser Machining Processes

1. Motivation of the project "Combined Research and Curriculum Development: Nontraditional Manufacturing"

Nontraditional manufacturing (NTM) processes refer to processes in which nontraditional energy transfer mechanism and/or nontraditional media for energy transfer are involved. The project is focused on nontraditional material removal or machining processes. They include electrical discharge and electrochemical machining (EDM/ECM), laser machining processes (LMP), abrasive waterjet machining (AWJM), among others. NTM processes can machine precision components from sophisticated materials. They offer the advantages of a reduced number of machining steps and a higher product quality. NTM can also exist within the realm of automated production. Interest in NTM has been on rise due to increasing interests in the vastly superior properties of innovative materials such as superalloys, composites and ceramics. NTM offers an attractive alternative and often the only choice for the processing of these materials. The new and potential applications require enhanced process capabilities and more precise process design and optimization capabilities. In response, substantial research progress has been made in recent years especially in the areas of process innovation, modeling, simulation, monitoring and control.

Progress has also been made in education of NTM processes. Education at the introductory level has been appropriate. Innovations and more orchestrated efforts, however, are needed at the upper level undergraduate and introductory graduate (ULUIG) curricula. NTM processes are diverse and of many types. They are also multi-disciplinary, involving thermal, fluids, chemical reaction, material science, system design and control theory. To teach research level materials at the ULUIG level, more time and effort are needed to prepare students. With more and more new research results being incorporated into courses with fixed credit hours, teaching efficiency and efficacy need marked improvement. Besides innovations in teaching methodologies, computer aided tools developed in research as well as computer aided teaching technologies offer great opportunities in this endeavor.

The objectives of this project, therefore, are:

Laser Machining Process (LMP) is one of seven modules of this project.

2. Preview of Laser Machining Process (LMP)

Laser machining is the material removal process accomplished through laser and target material interactions. Generally speaking, these processes include laser drilling, laser cutting, and laser grooving, marking or scribing.

Laser machining processes transport photon energy into the target material in the form of thermal energy or photochemical energy, they remove material by melting and blow away, or by direct vaporization/ablation. On the other hand, traditional machining processes rely on mechanical stresses induced by tools to break the bonds of materials. This basic difference in material removal mechanism decides the advantages and disadvantages of LMP compared with traditional machining processes.

In summary, laser machining processes are non-contact, flexible and accurate machining processes applicable to a wide range of materials. And they are in rapid developing. In fact laser machining is only a small fraction of laser related applications and all these areas are in rapid development. In this module we will discuss laser machining related topics.

3. Methodology behind this project

Energy, Material, System and InformationRapid advance in laser related technology has made more and more applications of lasers in mechanical engineering not only practical, but also efficient, precise, economical and flexible. The applications include Laser Cutting, Laser Grooving, Laser Drilling and Laser Welding, Laser Forming[4], Laser Cold Cutting, Laser Micromachining[5], Laser Surface Treating[1,2], RPM, Rapid Tooling[3], etc. Progress in laser processing comes along with other technologies which we call "Non-Traditional Manufacturing (NTM)" , such as Abrasive Waterjet Machining, Electrical Discharge Machining, Electrochemical Machining, Ultrasonic Machining, Ion or Plasma Machining, etc. The role of NTM is becoming more and more important in both industry and research.

As we are carrying out this NSF supported NTM research projects, we are impelled to think in depth not only the technical details, but also the philosophy and methodology behind traditional manufacturing, NTM and various new engineering thoughts.

First let's discuss the relation between traditional and nontraditional Manufacturing, then let's see the features of Laser Energy Field from a new viewpoint, finally let's talk about the organization of this module.

3.1 The Relation between Traditional and Non-Traditional Manufacturing [14]

Rising production costs dictates that production operations be automated whenever possible; innovative materials such as super-alloys, composites, ceramics and many other advanced materials, which are difficult to or cannot be processed by traditional machining methods, require new manufacturing technologies; environmental considerations require the development of Environmentally Conscious processes. NTM processes are often well suited to be monitored and controlled, the processing steps can be reduced with precision remains high. These are the impetuses for nontraditional manufacturing. In many cases, traditional manufacturing may have reached their capability limits, while NTM are offering the best resolution. But what's the difference between NTM and traditional manufacturing processes?

K. P. Rajurkar et al. Made the following statement[6]. "NTM processes can be broadly categorized in two ways: (1) processes in which there is a nontraditional mechanism of interaction between the tool and the workpiece, and (2) processes in which nontraditional media are used to effect the transfer of energy from the tool to the workpiece." In contrast, "Traditional Machining relies on direct mechanical contact between the tool and workpiece", which often cause undesired changes in the properties of workpiece, such as residual mechanical and thermal stresses. Figure 1 was used to summarize the common features of NTM. On the top and bottom are the interaction mechanisms and energy carriers or working medium, the energy transfer in a process can be continuous or pulsed, machining area can be local or full.

Figure 1. Generalized conditions diagram for Nontraditional Manufacturing processes (Rajurkar, 1992)

In some sense, traditional means things that are mature and widely accepted for some time. So the content of traditional changes with time. In some cases, the distinction between traditional and nontraditional manufacturing is not so obvious, for example, Abrasive Water-jet Machining uses mainly mechanical interaction, but it is commonly regarded as NTM; many new advances have been made in casting and thermal treating, but they been used for thousands of years.

In fact manufacturing has progressed into a time that many kinds of energy forms and interactions are coupled together, the combination of traditional and nontraditional manufacturing has produced many inspiring results. The strict distinction of traditional and nontraditional is not so important, but it is appropriate to regard mechanical force/energy as a common kind of force/energy, which is parallel to light, sound, electricity etc. Mechanical engineering needs constant innovations to meet various challenges. When we try to uncover the potentials of various manufacturing processes, it is important to purposely and systematically use various energy and energy fields to optimize our engineering solutions.

The essence of manufacturing engineering is utilizing information to control energy and mass to achieve human being's desired objectives. Figure 2 illustrates that three flows exist in any manufacturing processes (P), they are information flow (I), energy flow (E) and mass/material flow (M). The degree of combination or integration of the three flows can be used as index of process optimization[7].

Figure 2. Three flows in manufacturing processes

One common feature of NTM is the extensive use of various energy forms and energy fields, the whole engineering is in fact the art of energy field utilization and manipulation. Energy field means the distribution of energy or force, it is the area or space where a kind of energy or force can be felt. Some may think we normally use "point energy" which is not energy field, but point is a relative concept, it is localized energy field. A focused laser beam might be regarded as a point energy source, but for micromachining we must consider its spatial and temporal distribution. So energy field is a more general concept. Traditional machining commonly relates to stress field and thermal field, of course, gravitational field and environmental pressure field are always affecting any processes on earth. The more energy fields we consider, the more accurate and flexible can we control our processes.

Any kind of energy fields has its advantages and disadvantages, our aim is to find the best combination for our purposes. In addition to commonly known energy fields, such as mechanical forces, sound, light, electromagnetic and thermal fields, particle flows (such as electron beams, ion flows) and fluid flows, it is convenient to treat medium environment as a special kind of energy field--Medium Field. Medium distribution is regarded as energy field because different medium distributions can affect processing with great differences. Chemical machining and EDM need special medium environment to do their work. Reactive Laser Cutting uses Oxygen to assist cutting [8]. Different medium distributions can be defined to be of different energy states. This not only helps explain physical phenomena, but also can help quantify the effects of medium environment. Clever applications of Medium Field can be found in many realms, Lasers, diodes and transistors are such examples. Semiconductor Lasers and Q-Switch pulsed lasers are good examples of medium field, for details please refer [9].

3.2 Four Attributes Analysis of Laser Energy Fields

Building up a clear overall physical image first is important when we try to exploit various energy fields. Four Attributes Analysis of laser phenomena is very helpful for our research and modeling, it is useful to other energy fields as well. We will mainly use laser phenomena to illustrate Four Attributes Analysis of Energy Fields.

(A) Time AttributeVelocity, acceleration and feeding rate are part of time attribute. Temporal modulation of energy field has been proved to be an effective way to improve machining quality. We mainly discuss the time scale effects, continuous/discrete effects and the relativity effects of time attribute here.

The temporal distributions of energy fields can be of very different time scales, which can greatly affect the interaction between energy and material.

Heat Affected Zone (HAZ) for pulsed laser processing is usually smaller than that of CW laser processing. More striking phenomena were found when pulsed lasers progressed from ns scale (10-9 second) to under ps (10-12 second). For fs (10-15 second) scale laser processing, radical changes happened: heat affected zone decreased to almost zero at different wavelengths for the same material [10]. These were attributed to the ultra-short laser pulse duration. We briefly explain this as following. When laser beam acts on the material, laser energy is first absorbed by electrons. The absorbed energy then propagates through the electron subsystem, then transferred to the lattice. In this way laser energy is transferred to the ambient target material, as illustrated by figure 3. Three characteristic time scales are Te--the electron cooling time, which is in the order of 1ps; Ti-- the lattice heating time; and Tl--t7he duration of laser pulse. Te and Ti are proportional to their heat capacity divided by a same constant, and the heat capacity of electron is much less than that of lattice, so Te<<Ti. Te, Ti are decided by materials, Tl is what we can choose to make a difference. Three cases occur when Tl is in different ranges.

Figure 3. Energy flow in laser-material interaction

Case one: Tl >1 ns >>Ti>>Te. In this case, electron absorbed laser energy has enough time to be transferred to lattice, electron and lattice can reach thermal equilibrium, the main energy loss is the heat conduction into the solid target. Material is first melted, when the beam is strong enough, evaporation occurs from liquid state. The existence of melting layer makes precise material removal using laser pulses above nanosecond very complicated. Case two: Ti>>Te>>Tl, Tl is of fs scale, laser pulse duration is shorter than the electron cooling time. Electrons are heated instantly, then in about 1 ps electrons transfer their energy to their positive lattice ions. When this energy intensity is high enough, which is often true for ultra-fast pulsed lasers, those ions get energy high enough to break the bonding of lattice structure, they break off instantly without having time to transfer their energy to their neighboring lattice ions, thus direct solid-vapor transition occurs. Heat conduction into the target can be neglected, heat affected zone is greatly reduced. For melting-free ablation to be possible, two conditions must be met: ultra-short pulse duration and high enough pulse energy. Case three: Ti >>Tl>>Te, Tl is of ps time scale. This is a transitional situation, melting layer exists in laser ablation.

The temporal distributions of energy fields can be continuous or discrete, both have their advantages and disadvantages relative to their applications, it's bias to think either of them to be better forever, their relation is similar to analog and digital circuits. Both CW lasers and pulsed laser are used widely in laser machining. The interaction between Grinding and multi-threads drilling tools and parts are also discrete. Consider the following example. Usually vibration can do harm to precision in machining, but it is reported that by using ultrasonic pulse cutting, the lathe tools get great instantaneous speed and accelerate in a very short period, high energy is exerted in a very limited area. This process smoothly transforms plastic materials to relatively brittle state, cutting force is decreased, cutting time is shortened, cutting heat is minimized and residual stress is greatly relieved [11]. This process solved many otherwise commonly met difficulties by using energy field method--change continuous cutting to discrete micro-cutting, this is a typical example of energy field temporal modulation.

An important time duration effect is that when the energy field intensity and energy pulse duration reach certain extent, something unusual may happen. This doesn't limit to the two examples we gave, this should be an effective way to uncover the potentials of various energy fields. We should also be aware of the relativity of time effects. Relative to very fast events such as very short energy pulses, the event varying at normal speed can be treated as static. Below a corresponding time scale, objects usually demonstrate very abnormal properties. For example, the property of liquid can change for different time scales, below 10-12 second, water can not be treated as Newtonian fluid anymore.

(B) Spatial Attribute

Spatial distribution of energy field is directly related to energy acting area, acting location and relative position between tool/energy sources and parts.

Laser can be transmitted over long distances with very small divergence, laser beam spot size can vary from 1 m m to 10 mm. Highly focused beams can act locally with high intensity, which are used for precision material removal, defocused laser beams are used for surface treating, laser forming, etc. In laser machining the relative position between laser source and parts is important. Optical fibers have been used in communication for a long time, now they are used to carry high power laser beams in manufacturing, they add valuable flexibility in laser energy transmission. It's the refractive index difference in the fiber system that makes low loss light energy transmission feasible. Waterjet in air forms a natural waveguide system for laser beam, this property has been used in US patent 5292498: Local Laser Plating Apparatus. Spatial adjustments of energy fields are widely used to achieve various objectives. Telescope, microscope, thermal couple are representative examples.

Why are pulse duration time and focus spot size so important in laser processing? It will be clear after we have examined some energy indexes. Peak Power equals pulse energy divided by pulse duration time, Intensity is the area average of peak laser power. When the interaction between energy field and target is not continuous, energy intensity is usually the deciding factor. Let the absolute energy in a laser pulse be 0.1J, fixed. Let pulse lasting time be dT second, let pulse repetition rate be f Hz, and 1/f > dT. Let the beam focused spot size be D cm in diameter. If pulse repetition rate can vary in the range of 1Hz~4kHz, then average power is f*E = 0.1~400W. Let's vary pulse length and acting area, compute the peak power and intensity. We see clearly from the figure below, peak intensity of a 10 fs pulse with D=1 m m is 1022W/cm2, while the intensity of a 1 m s pulse with D=1 mm is107W/cm2.

Figure 4. Laser intensity & beam size and pulse duration

(C) Frequency Attributes

Human beings have accumulated plenty of resources relating frequency properties of energy field, we can expect more advanced manufacturing processes to be invented by applying frequency modulation rule. Laser material processing is just one of such examples. The frequency here is the characteristic frequency of energy field, which is different from Pulse Repetition Rate. Radio wave, microwave, sound wave, mechanical vibration, lattice vibration, gas molecule collision, etc., all have their respective characteristic frequencies. Thermal radiation has spectral distribution, many other energy forms or material properties are also related with frequencies. Lasers usually have very narrow spectral width, while other energy forms may have very broad and complex frequency distributions. Some energy field's characteristic frequency is not obvious, such as gravitation field, medium field, thermal energy, stress energy, vacuum field, fluid pressure field etc. Their frequency distributions are either being discovered or are nearly zero.

The characteristic frequency of energy field is important because materials may response very differently to energy fields at different frequencies. UV laser ablation of organic polymers is very different from infrared or visible laser ablation, their ablation mechanisms are very different [13]. The infrared and visible laser ablation is mainly photo-thermal degradation, while UV laser ablation involves direct photo-chemical dissociation. The emissivity of copper varies with wavelength as seen in table 1. That's the reason why lasers at different wavelengths are used to process different materials.

Table 1: Spectral emissivity e l of Cu at different wavelength(m m), T=293K, normal to surface[10]:

|

l |

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

|

e l |

0.67 |

0.5 |

0.4 |

0.2 |

0.03 |

0.02 |

0.02 |

The diffraction free focus spot size is proportional to light wavelength. For circular beams, the focal spot size is:

Dmin= 2.44f*l /D

where f is the lens focus length, l is the light wavelength, D is the unfocused beam diameter. This defines the upper limit of laser processing precision at a specific frequency. Thus for high precision applications, short wavelength lasers are preferred.

(D) Amplitude Attributes

Frequency and amplitude are closely related. Amplitude or magnitude is a direct measure of energy field intensity, deciding what amplitude is proper or optimal is our everyday work. For energy field method, we are interested in the effective ways of amplitude modulation and the direct or indirect amplitude effects of various energy fields. In optics, optical filters, polarizers, attenuators, beam expanding and focusing systems are used to modulate laser intensity and spatial distribution. With their help, we can match the laser power output to very different applications in the same time without disturbing the laser source.

A common rule relating the amplitude of energy field is: certain valve value exists for the interaction between material and energy field, below this value, the interaction mechanism may be simple and linear, beyond this value, the mechanism becomes nonlinear, and at extreme conditions, striking abnormal phenomena will happen. This indicates that some kind of transition mechanism between frequency and amplitude exists, or we can say, the effect of amplitude adjustment is somewhat equivalent to the effect of frequency adjustment. An example is self-focusing of laser light. When laser intensity is high enough, media refractive index changes. Usually the higher the intensity, the bigger the refractive index. Since the center of a Gaussian laser beam has higher intensity than the rims, when the beam passes through optical medium, central area has bigger refractive index than the circumferential parts, equivalent lens focusing effect occurs. When we have reached the extreme of normal focusing systems, using this method can further focus the spot to 1/5! Remember machining precision is decided by the smallest spot size achievable, this is equivalent to a new laser source whose wavelength has been reduced to 1/5 of original.

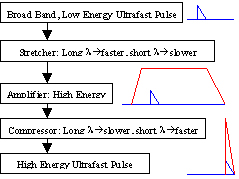

Modulators usually saturate or even burn down at too high magnitude of energy flow. If modulators can only work at low energy level, but we must generate ultrahigh energy flows through them, what shall we do? We can wait until modulators that can withstand the required high energy be produced or we can learn something from ultra-short pulsed lasers. Let's jump over the technical and physical principles details, then we can focus on the general rules inside. Ultrafast laser oscillators generate pulse energy initially at nJ (10-9J) scale, amplification to mJ level is needed in micromachining, but we know, when pulse lasting time is very small, peak energy intensity goes up far beyond the safety operation range of normal optical amplification systems. Ultrashort pulsed lasers successfully solved this difficulty using Chirped Pulse Amplification (CPA) and Pulse Compression techniques. The energy of ultrafast lasers are highly concentrated in time domain, but their frequency distributions are much broader than normal laser systems. Light at different frequencies travel at different speeds through optical mediums. This is a bad thing at first glance because we normally desire same rules being obeyed by as many objects as possible. Contrary to our intuition, this forms the base for the final solution. Figure 5 illustrates the idea. In free space, different components in a broad band laser pulse travel at nearly same speed, time concentration of the beam is kept. When normal optical components are in the optical path, long wavelength light components travel through the medium faster than short wavelength components, thus pulse lasting time is stretched, energy intensity is lowered. Special optical devices such as chirped mirrors or special prism pairs are used to compensate the pulse spreading, they allow short light components pass through faster than long wavelength components, so they compress pulse lasting time. When stretching and compressing are used together, the solution is there!

Figure 5. Principle of ultrafast laser systems

The enlightenment of this example is: time, space, frequency and amplitude of energy field are interconnected, no property is absolutely positive or negative to our ends, by properly making use of these properties, we can usually circumvent difficulties unavoidable by normal ways.

3.3 Organization of the Module: Laser Machining Processes

The Module will be presented in terms of three broad topics: Energy, System and Material, to reflect the philosophy we have discussed and to facilitate possible coordination with other modules of this project.

Each topic will be presented in three levels: Introductory, Intermediate and Advanced, to suit different needs.

The Introduction level will include the most basic phenomena, mechanisms and theories. Qualitative description will be emphasized and simple quantitative relations may also be included. The purpose is to give an overall basic understanding of LMP. Introductory level is for beginners or those who just want to get a general and basic understanding of the laser machining process. The contents are feature as descriptive and qualitative, mathematics is purposely reduced.

The Intermediate level will include all important phenomena, mechanisms and theories. Quantitative relations will be emphasized and analytical tools will be provided. Some recent research results will be included. This level prepares for in-depth understanding and for advanced research. Intermediate level is aimed to give a relative complete knowledge of the laser machining process. It is self-contained, but some references are made to level one to avoid repetitions. More theoretical aspects of laser machining processes are presented than level one. This level is for upper-level undergraduates and first-year graduates. The contents is systematically organized to make it suitable for self learning, as a text or as a useful references for a university course about laser machining processes.

The Advanced level will include the relatively special phenomena, mechanisms and relatively more advanced theories and analytical tools that primarily target graduate students and researchers. Recent research results will mostly be included here.

These three levels can be taken sequentially or individually. The above structure will be convenient for cross-referencing, especially when it is implemented on the Web. Multimedia techniques are used to make the web different from a paper-textbook: you can click to see the definition of a term, you can jump to any interested link, you can try the interactive relations, etc.

Next let's give a brief review of the contents in the module.

4. Brief review of the contents in this module

In order to understand the mechanism of laser machining processes, the basic principles of lasers are instroduced in Chapter 2 "Laser Basics". Laser was invented in 1960, but the invention was based on previous works in theoretical physics. In level 1, the history of lasers was presented. Then the properties of laser beams, basic principles of lasers, basic constructions of laser cavities and the concept of laser modes discussed. Common industrial lasers, such as carbon dioxide lasers, Nd:YAG lasers were reviewed. Important parameters of lasers were discussed at the end of chapter 2 level 1.

Chapter 2 level 2 gives a detailed discussion of laser basics. Concepts of Black Body Radiation, Energy Levels, Spontaneous Emission, Stimulated Absorption and Emission were introduced to illustrate the principles of laser generation. Rate equations were used to illustrate the population inversion and amplification mechanisms in laser resonators. Various laser resonators and quantitative description of laser parameters are presented. The polarization, reflection, absorption and trasmission of laser beam has practical meaning in laser machining processes and were discussed in section 2.8, 2.9. Besides common industrial lasers introduced in level 1, excimer lasers, semiconductor lasers are reviewed.

Chapter 2 level 3 discussed solid state lasers and ultrashort pulsed lasers which are progressing very rapidly and attracting more and more attentions. Diode pumped lasers has many advantages such as compactness, high efficiency, high stability, etc., are discussed and explained. The principles of ultrashort lasers are presented in a step-by-step manner. The techniques to generate pulsed lasers were introduced first, then the special techniques to generate ultrashort pulses were talked.

Chapter 3: Energy Transfer and Modeling

Laser machining is a thermal process which removes material through phase changes (melting, vaporization). Energy transfer and modeling is the core of this module. It is crucial to understand, to predict and to control the laser machining processes. Chapter 3 levels 1 first reviewed laser machining processes, then discussed how to describe laser energy. The interaction between laser beam and target materials was detailed. A brief introduction of LMP modeling was given in Section 3.4. The role of gas jet and thick section laser cutting were discussed at the end of level 1.

Chapter 3 level 2 continues the modeling effort in level one. The basic knowledge of heat trasfer and fluid dynamics was reviewed, the conservation laws of mass, momentum and energy were emphasized. Models with analytical solutions are useful for getting some understanding of the physical process involved, but analytical solution can only be got for simple conditions. Once complex geometry, boundary conditions, nonlinear phenomena are involved, it will be difficult to get analytical solutions, even if the above mentioned complexity can be described with simple mathematical relations. But the basic laws governing the physical process still apply. In real life, numerical solutions are sought when analytical solutions are not available. Numerical methods are discrete methods, they developed quickly with the development of computer technology. Models with analytical solutions were discussed in section 3.5, and a primitive introduction of numerical methods were discussed in section 3.6. The gas jet effects in laser machining was discussed in-depth at the end of level 2.

Chapter 3 level 3 try to build a general image for the modeling of laser machining processes, advanced models were introduced. Section 3.1 summarized the steps in modeling. The boundary conditions are very important in modeling and were discussed in section 3.2. Both fluid flow boundary conditions and heat transfer boundary conditions in laser machining were incorporated. The models for cutting geometry prediction was presented in section 3.3. The laser machining process is complex, so many models have been suggested, can we extract some general information from the existing works? Generalized governing equations in LMP were discussed in section 3.4. The general governing equations can be applied to single phase mediums directly, such as one hundred percent liquid or one hundred percent solid. Heat transfer without phase change is relatively easy to deal with. But laser machining is featured with intense phase changes from solid to liquid, from liquid to solid, from liquid to vapor, or even directly from solid to vapor. Further more the solid-liquid interface is changing violently considering the usually very short laser-material interaction time. Under such circumstances, the numerical computation should take special considerations on the boundary condition. The widely adopted enthalpy method and the concept of Knudesen layer discontinuities were discussed to tackle these phase related issues.

Chapter 4: System (Underconstruction)

In chapter 4, the functions of laser optical transmission components were reviewed first. The various sensing and controlling techniques were then reviewed. This chapter try to draw the reader closer to the practical laser machining systems. System, information, and control are closely related, they form one of the important elements in the NTM model introduced previously. The progress in the integration of sensing, CAD/CAM and control was reviewed.

Laser machining of different materials have different features. For this purpose materials in LMP were discussed in chapter 5.

In chapter 5 level 1, laser machining of metals, polymers, composites as well as semiconductors were summarized. The fundamental issues and applications of such materials were presented. Conventional laser machining of materials(CO2 laser machining of materials, Excimer laser machining of materials, YAG laser machining of materials) and general materials issues considered in laser machining procress were discussed at the end of level 1.

In chapter 5 level 2, laser machining of other materials, such as ceramics, metal-matrix composites and superalloy, were discussed. These materials can be very difficult to machine using other methods, however laser has proved to be a very effective solution. Frequency doubled and tripled YAG lasers laser machining, short pulse high density laser machining and diode pumped laser machining of materials were reviewed.

In chapter 5 Level 3, some new trends in laser machining processes were reviewed. Section 5.1 presented diode Laser machining, section 5.2 reviewed ultra-short pulsed laser machining, and finally section 5.3 described three dimensional micro-structuring in materials.

References:

[1] Geroge Chryssolouris, "Laser Machining", New, Springer-Verlag, 1991;

[2] William M. Steen, "Laser Material Processing", London, Spring-Verlag, 2nd Printing 1994;

[3] Yongnian Yan et al., "Progress in Rapid Prototyping Manufacturing and Rapid Tooling", Proceedings of ICRPM'98, Beijing;

[4] Wenchuan Li, Jiangcheng Bao, Y. L. Yao, " Dimensional characteristics and mechanical properties of laser-formed parts", High Temperature Material Processes, invited paper;

[5] X. Liu, D. Du and G. Mourou, "Laser Ablation and Micromachining with Ultrashort Laser Pulses", IEEE Journal of Quantu Electronics, Vol. 33, NO. 10, Oct., 1997, p1706-1716;

[6] K.P. Rajurkar et al., "The Role of Nontraditional Manufacturing in Future Manufacturing Industries", P23, Manufacturing International 1992;

[7] Feng Lin, "Research on the Principle of Slicing Solid Manufacturing Process and The System Development", doctor dissertation of Tsinghua University 1997, China, P73;

[8] William M. Steen, "Laser Material Processing", London, Spring-Verlag, 2nd Printing 1994, p80;

[9] Orazio Svelto, "Principles of Lasers", 4th edition, New York, Plenum Press, 1998, chapter 8;

[10] B. N. Chichkov et al., "Femtosecond, picosecond and nanosecond laser ablation of solids", Appl. Phys. A63, 109-115 (1996);

[11] Junlan Sun, Dazhi Jiang, "Vibrative cutting mechanism research and its applications", Mechanical Manufacturing (China), p6-7, 04/1997;

[12] Igor S. Grigoriev, Handbook of Physical Quantities, CRC press;

[13] R. Srinivasan, Bodil Braren, "Ultraviolet Laser Ablation of Organic Polymers", Chem. Rev. 1989, 89, 1303-1316;

[14] Wenwu Zhang, "Study on RPM, 3DM and Energy Field Formics," Proceedings of ICRPM'98, Beijing, p316-320;